Infrared and Laser Barcode Scanners: Technologies Behind UPC Label Reading

Introduction to Barcode Scanning Technologies

Barcode scanners are essential in retail, logistics, healthcare, and manufacturing, enabling fast and reliable data capture from Universal Product Code (UPC) labels. Two primary technologies dominate this space: infrared and laser scanners. Both offer distinct advantages and are widely used to read UPC labels efficiently. Understanding how these technologies work, their benefits, and practical steps for implementation is crucial for businesses seeking to optimize their operations.

How Laser Scanners Read UPC Labels

Laser barcode scanners use a focused laser beam to read barcodes. The process begins when the scanner emits a laser onto a barcode, typically using an oscillating mirror to sweep the beam across the code. This enables rapid reading of linear barcodes like UPCs. The scanner’s sensor detects the intensity of the reflected light: white spaces reflect more light, while black bars absorb it. The scanner converts these light variations into electrical signals, which are then decoded to produce the product information.

One of the main advantages of laser scanners is their speed and accuracy. High-end models, such as the BL-1300 Series, can achieve up to 1300 scans per second, ensuring fast throughput even on busy retail lines or high-speed production environments [2]. The technology’s ability to filter out noise and correct for dirt or blurred markings allows for reliable reading of even damaged or faint codes.

Laser scanners are typically unable to read 2D codes but excel with 1D barcodes like UPCs, making them particularly suitable for retail and warehouse applications [3].

Infrared Technology in Barcode Scanning

Infrared barcode scanners use near-infrared or infrared laser diodes as their light source. These scanners illuminate the barcode with infrared light, enhancing image quality and contrast, especially in challenging lighting conditions. Infrared enables several benefits:

– Enhanced Accuracy: Infrared illumination increases the contrast between the bars and spaces, improving data capture and decoding. – Improved Efficiency: Infrared aids auto-focusing and image enhancement, allowing scanners to work quickly and clearly, even in environments with poor ambient lighting. – Expanded Applications: Infrared scanners can be used in a broader range of settings, including those with high ambient light or reflective surfaces, offering versatility for logistics and industrial use [1].

Infrared technology is commonly found in advanced camera-based imaging scanners and some slot-type barcode readers. These devices leverage infrared to boost reliability and scan performance.

Key Components and Operation

Laser-based barcode scanners consist of several critical components:

– Laser Diode: Emits a coherent laser beam for scanning. – Oscillating Mirror: Sweeps the beam across the barcode. – Detector (Photodiode): Captures reflected light and converts it into an electrical signal. – Decoder: Interprets the signal to extract barcode data.

For infrared scanners, similar components exist, with the primary difference being the light source wavelength. Near-infrared illuminators are used to enhance the barcode’s visibility to the sensor, especially in imaging-based systems [1].

Real-World Applications and Case Studies

Retail: Laser scanners are ubiquitous at checkout counters, reliably scanning UPC labels on products. Their speed and accuracy minimize waiting times and reduce errors.

Warehousing & Logistics: Extended range laser scanners can read barcodes from distances up to 45 feet, ideal for scanning codes on high shelves or pallets [4]. Infrared-equipped scanners work well in environments with challenging lighting or reflective packaging.

Manufacturing: Barcode scanners-both infrared and laser-enable rapid tracking of materials and products throughout the supply chain, supporting inventory control and asset management.

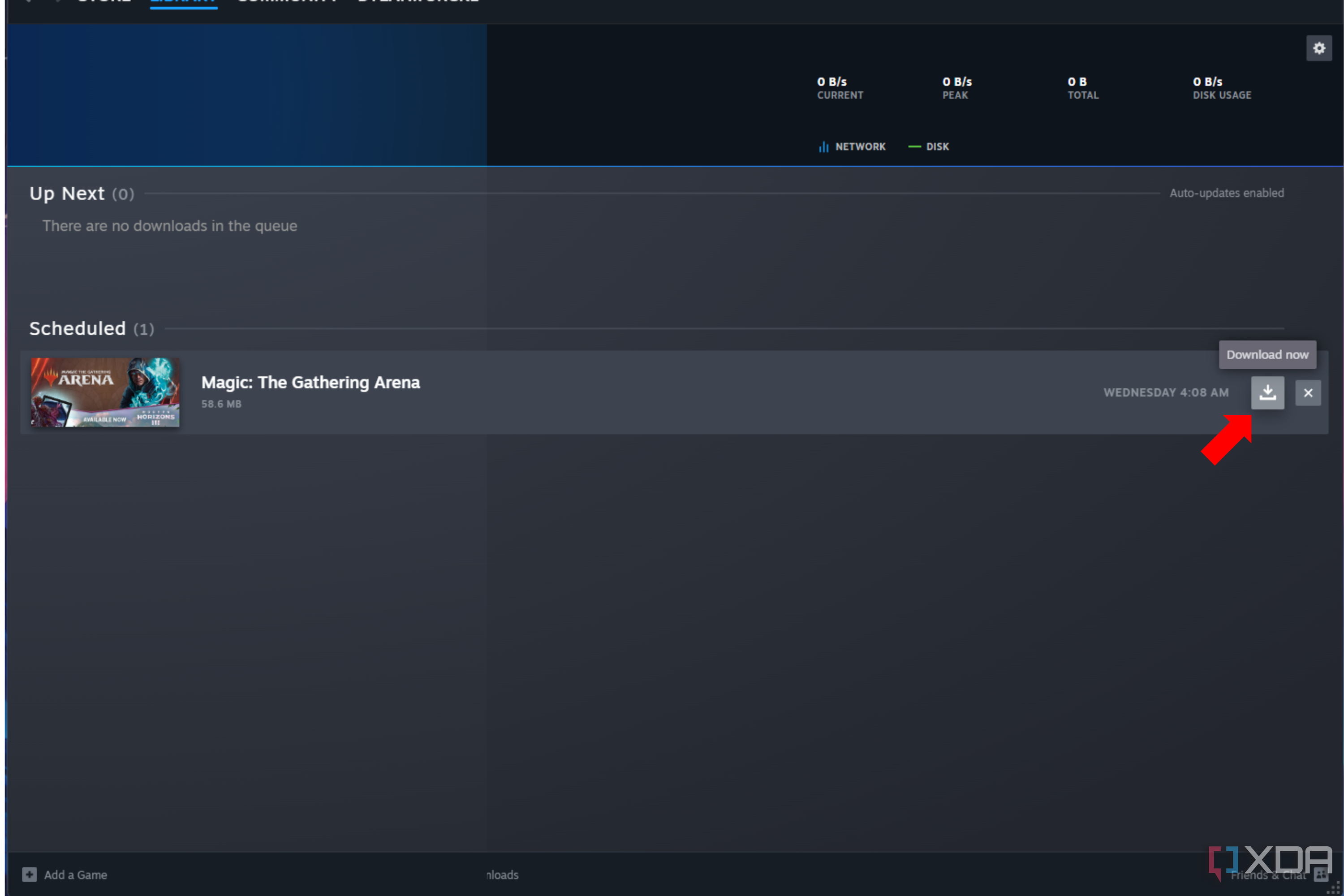

Implementation: Step-by-Step Guidance

1. Assess Your Needs: Determine the types of barcodes you need to scan (UPC, other 1D, or 2D). Laser scanners excel at 1D codes, while infrared/camera-based scanners can handle both.

2. Choose the Right Technology: For high-speed retail or warehouse environments, select a laser scanner with proven reliability and distance capabilities. For environments with poor lighting or reflective surfaces, consider infrared-enabled imaging scanners.

3. Evaluate Features: Look for scanners offering automatic tuning, wide field of view, high-speed decoding, and noise correction. Compact models may be preferable for space-limited installations [2].

4. Installation and Training: Install scanners according to manufacturer specifications. Train staff on proper usage, focusing on aim, range, and handling of damaged or obscured barcodes.

5. Integration: Ensure that your scanner can connect with POS, inventory, or asset management systems. Most scanners offer USB, Bluetooth, or network connectivity.

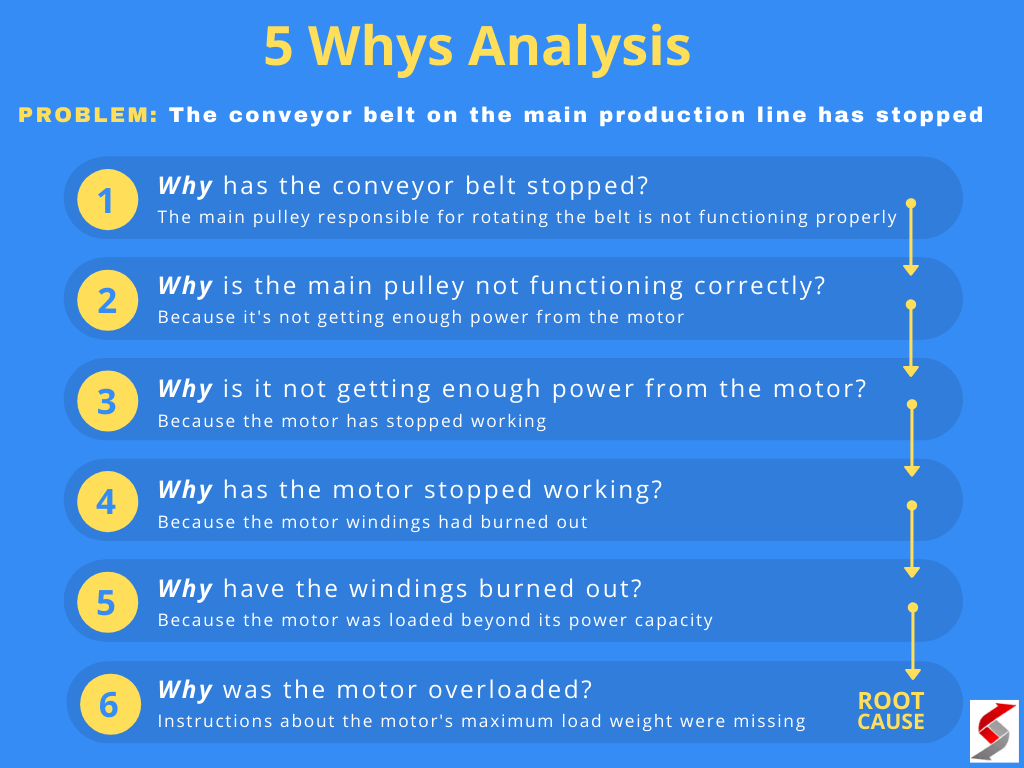

Potential Challenges and Solutions

Challenge: Scanning damaged or dirty barcodes.Solution: Use scanners with advanced noise correction and edge detection features to reliably extract data from compromised codes [2].

Challenge: Reading barcodes at a distance.Solution: Invest in extended-range laser scanners for warehouse applications, as these can scan from much farther away than imagers [4].

Challenge: Scanning in challenging lighting conditions.Solution: Infrared technology helps reject ambient light and provides consistent illumination, improving scan reliability [1].

Alternatives and Emerging Technologies

If your needs extend beyond 1D codes, consider camera-based imaging scanners. These use advanced sensors (often with infrared illumination) to read both 1D and 2D codes, offering flexibility for future-proofing your operations [1]. Imager scanners are increasingly closing the performance gap with lasers, especially in terms of speed and range [4].

How to Access Barcode Scanning Solutions

To acquire a barcode scanner, you can:

– Contact leading manufacturers such as Zebra, Honeywell, or Keyence. Visit their official websites to explore product specifications and request quotes. – Consult with IT solution providers specializing in retail or warehouse automation. – Research scanner models to compare features, range, and compatibility with your systems.

When purchasing, consider reaching out to authorized distributors or searching for industry reviews to ensure you select a reliable model that meets your operational requirements.

Summary and Key Takeaways

Infrared and laser barcode scanners are proven technologies for reading UPC labels, offering speed, reliability, and adaptability. Laser scanners excel at distance and speed, while infrared-equipped scanners ensure performance in challenging environments. Assess your needs, compare solutions, and work with reputable suppliers to implement the right system for your business.

References

- [1] Wavecreating Micro Intelligent (2024). Do Barcode Scanners Use Infrared?

- [2] KEYENCE America. Barcode Scanners

- [3] FindLight (2023). Barcode Scanners and the Underlying Technology

- [4] TrackAbout (2022). Laser Scanner or Imager for Barcode Asset Tracking – Which Is Better?

- [5] Free-Barcode.com. Laser-Based Barcode Scanners

MORE FROM gowithdeal.com